Experienced professionals can check areas that are locations of common weaknesses in the roof assembly and identify problems early on before they cause damage to your roof and the structure of the building.

Tpo roof condensation problems.

The biggest problem with good quality tpo that.

Tpo is generally environmentally friendly and mold and algae resistant.

While this roofing system can be walked on and it is both flexible and lightweight the membrane itself can be easily punctured.

Cool roofs can include asphalt built up membranes like fiberglass modified bitumen and torchdown.

Although condensation in roofs may not seem like a serious problem it actually is.

Since the roof in question is 1575 s f.

Cool roof temperatures may increase the possibility of condensation if warm moist air from the interior comes into contact with the assembly.

And even shingles explains dale w.

A professional roofing contractor or roofing consultant should review your roof system on a regular basis.

These roofs have few inter material condensation problems for two reasons.

In the building industry tpo stands for thermoplastic polyolefin a synthetic rubber compound that has been extensively used for roofing since the late 1980s.

Single ply membranes like tpo pvc and epdm.

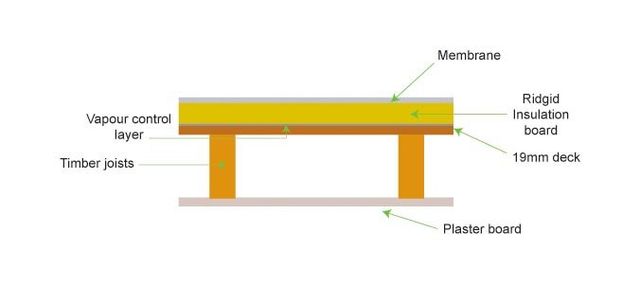

And second the roof deck and rigid insulation form a reasonable interior vapor barrier.

It is the leading cause of the deterioration of trusses.

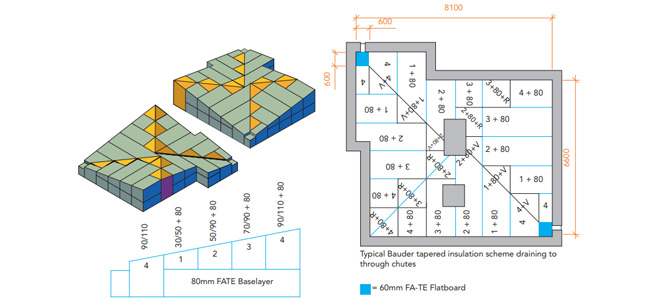

Half rolls are used for perimeter sheet.

Genflex installation instructions are unclear about the use of perimeter sheet.

Structural damage and improper installation cause a lot of the tpo problems.

First there is little air movement within the roof system to pump moisture laden air into the roof.

Tpo membranes can be applied directly over old existing roofing material or a bare roof deck with adhesive or mechanical fasteners.

Of all the tpo roofing problems there are this is the one that is probably the most problematic.

This applies to both the timber and steel trusses.

In the case of the timber trusses and purlins they will rot and eventually lose their stability.

It is made up of a single ply synthetic membrane used to cover flat and low slope roofs.

Tpo roofing membranes have been noted to have an issue of accelerated weathering when subjected to high thermal or solar loading.

We will need 2 rolls of 10 100 of tpo and 3 full rolls of ib 6 90 and 2 half rolls of ib 3 90.

This problem has been specifically documented in the southern states that get a lot of heat and sun throughout the year.